If you decide to become a landlord, it is your responsibility to provide your tenants accommodation that is fit for living. The standard of the property should adhere to the Landlord and Tenant Act 1985, wherein it has to be structurally sound and in good repair, with natural lighting and facilities for hygiene. To make it appropriate for the colder months, the property will also need enough insulation and water and electrical supply. This means the landlord has four main responsibilities when caring for his or her tenants:

Build or furnish a property that is free of health hazards

If you want to place a fireplace or a wood-burning stove in any of the rooms, you need to ensure to fit a carbon monoxide alarm. Using the right, high-quality materials for the place can also hinder any damages that are detrimental to your tenants’ health. This also means regularly scheduling inspections done by professionals.

Ensure that there are fire safety tools in place

In relation to the previous point, it is also helpful to have your walls made of fireproof material (or check if it is up to the standards of the 1988 Fire Safety Regulations). Because it’s best to prepare for any calamities, natural or manmade, the best way to appreciate your property’s value is by keeping its build sturdy. Always have a fire extinguisher, fire blankets and fire alarm in places where fires are more likely to start (e.g. kitchen area, fireplace, boiler room, etc). You must also ensure that the furniture meets the same standards, checking the manufacturer’s label if they are fire-safe.

Carry out repairs once faults and defects are detected

Once the place is furnished, it is also the landlord’s responsibility to keep it in top shape. Of course, this will also depend on how quickly your tenant can report these faults may they be moulds, infestation or short circuits.

Install and test if gas and electrical appliances work according to industry standards

According to the 1994 Electrical Equipment Regulations, all of your electrical equipment needs to be regularly tested by a professional, ensuring that wirings are concealed and plugs are BS1363 compliant. Meanwhile, fire-guards need to be BS3248 compliant, and fire extinguishers need to be BS6575 compliant.

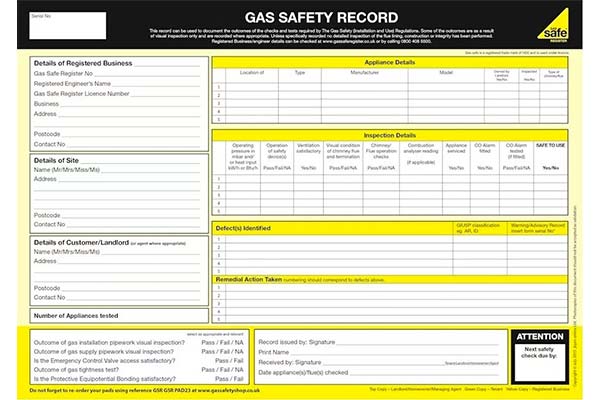

If the gas appliances are your own and not the tenant’s, you are required to have a Gas Safe engineer check if they are safe and in good working order. The 1994 Gas Safety Regulations also require a landlord Gas Safety Certificate that is valid for one year. Make sure to keep a record of these safety checks and give your certificate within the 28 days that a potential tenant agrees to the tenancy contract.

Gas Safety: The Most Important Certificate Of All

While you have a lot of legal obligations to your tenant, procuring a Gas Safety Certificate is the first and most important step when keeping your property in the market and winning a potential tenant’s trust. Widely known as the CORGI Proforma or CP12, this takes note of the dates that all of the gas appliances in your property have been checked by a Gas Safe registered engineer. These people are the only ones qualified and certified to ensure the safety and the efficiency of your appliances. You can find the official list on Gas Safe’s website.

If your tenant owns the gas appliances, it is still your duty to have the flues and fittings regularly checked. While these may be time-consuming on your end, a whiff of gas in a home can turn into something more dangerous had it not been prevented. Here are some risks landlords may encounter is the compliance system is ignored or bypassed:

Gas leaks: The first sign of a faulty stove, fireplace or pipeline is the smell of gas that lasts for longer than normal. While it may not be poisonous, these things can quickly escalate into fires or explosions if not handled immediately. If your appliances are not being regularly maintained or checked, the metal will start to rust through and pipes will start to have a green discolouration.

Fires and explosions: Because of continued neglect or a sudden action, the gas can explode into flame really quickly. Once exposed to a sudden spark, the fire can spread throughout the building and cause great damage to your property and to the lives of your tenants.

Carbon Monoxide Poisoning: If your kitchen is not well-ventilated and your LPG gas burns incompletely, your tenants may report experiencing sleepiness and lethargy. Before they get sick and report your unit to authorities, it will be better to install a detector in the kitchen and have your appliances regularly checked instead.

When a gas engineer arrives at your property, the inspection normally starts with checking the density of your appliances and verifying the standing and working gas pressure. Afterwards, the engineer also checks the manufacturer’s nameplate for a burner or gas pressure and assesses if your appliance is placed in a room with enough ventilation. A smoke flow test will also be conducted to ensure that there are no combustion products anywhere near your appliances. Once the safety devices are checked, engineers also look if the gas appliance has been misused in any way.

Normally, if your gas appliance is damaged or dysfunctional, the engineer will carry out repairs. Because of this, you may incur additional charges before you can get your certificate. That said, we recommend properly cleaning and maintaining your gas appliances to avoid higher rates. If you notice potential damage, we also advise calling professionals immediately. With the previous risks that we explained, dealing with gas problems can be tricky and dangerous if handled with inexperienced hands.

Once you have your property checked, you will receive your compliance certificate within ten to fifteen working days. If you are due for a yearly maintenance check for your appliances, our Gas Safe registered engineers are available to provide gas and plumbings services throughout London. Simply contact us here and we can schedule our visit to your property immediately.